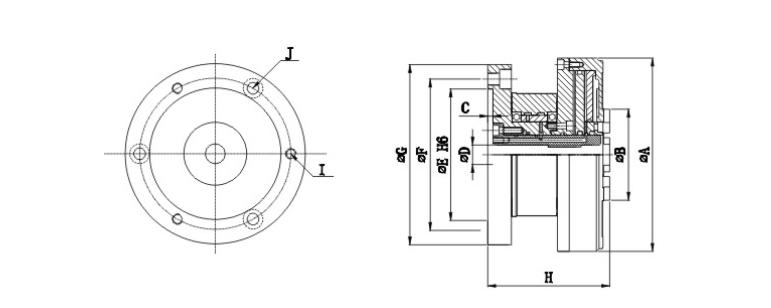

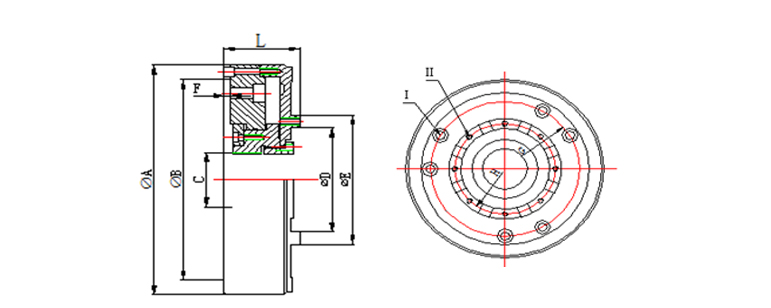

Product Features:

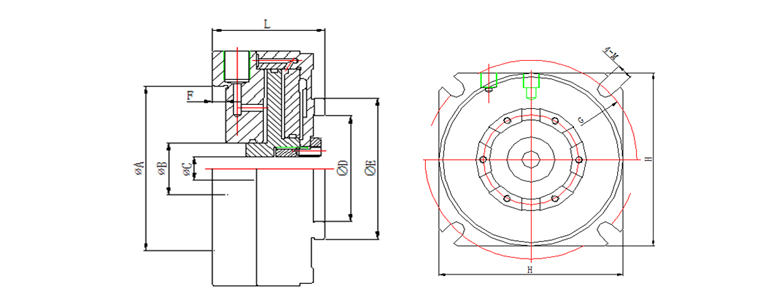

● Use membrane elastic technology, repeat accuracy below 5μ

● Permanent precision life

● High -sealed design, waterproof and dustproof ability

● Easily control both ends and parallelism

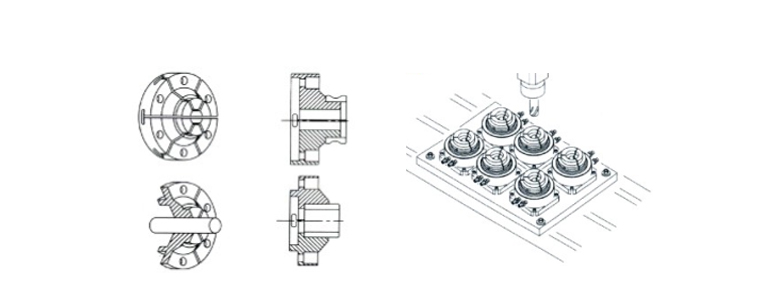

● Multi -segment size can be processed and reduced equipment costs

● Use a single motion grinding machine to replace CNC multi -segment processing at the same time

● The hidden in the air pressure cylinder is directly driven

● It can be fine -tuned for precision and fine -tuning with three -point combination.

Product Suitability:

● Precision processing of miniature bearing, motor, precision set

● It is suitable for microelectronics, optical parts, medical parts, car, and thin and high -precision workpieces, grinding processing

● Detection of precision components