Several difficult problems of traditional driving processes during the car cutting process at both ends of the workpiece:

1. When the two ends need to be processed at the same time, you need to do second -time independent processing, which is high in manpower and equipment. > 2. The clamping reference variable generated by the secondary clamp cannot be controlled;

3. When the workpiece has concentric requirements, the secondary clip variable benchmark cannot be controlled and ensured that the concentric requirements are required.

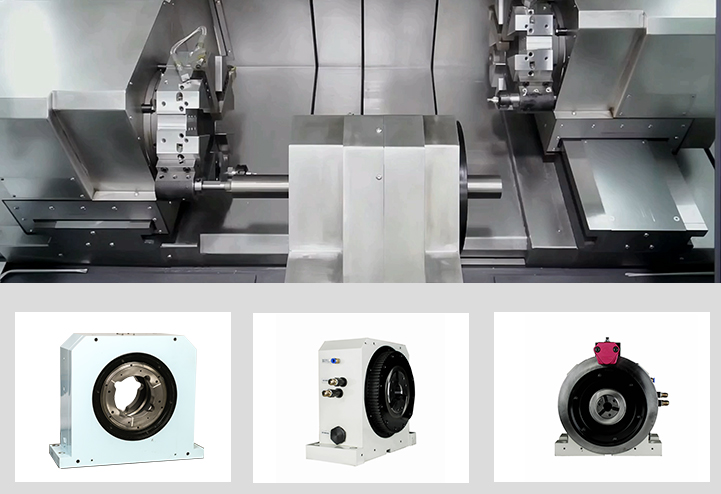

For the solution of the above -mentioned difficulties, the development of the two -way spindle clipper came into response, and the core unit promoted the industrial development of the double -headed CNC lathe.

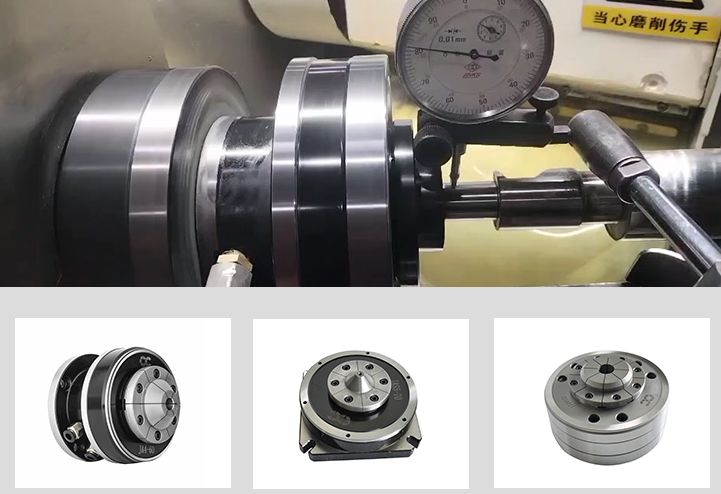

Application case video