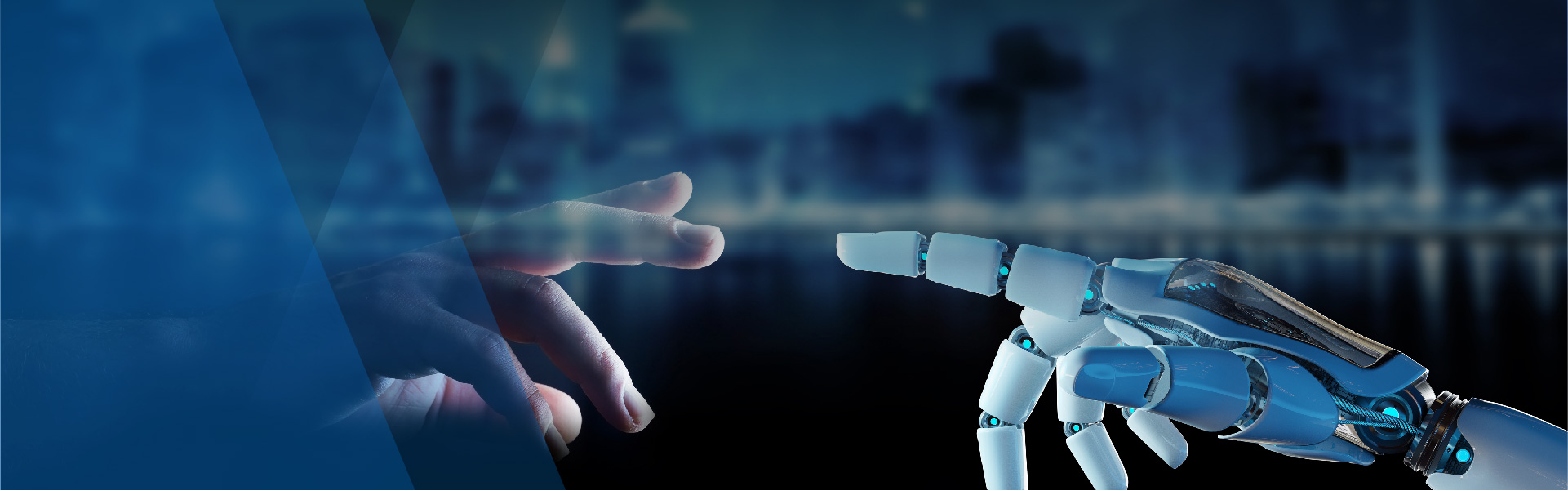

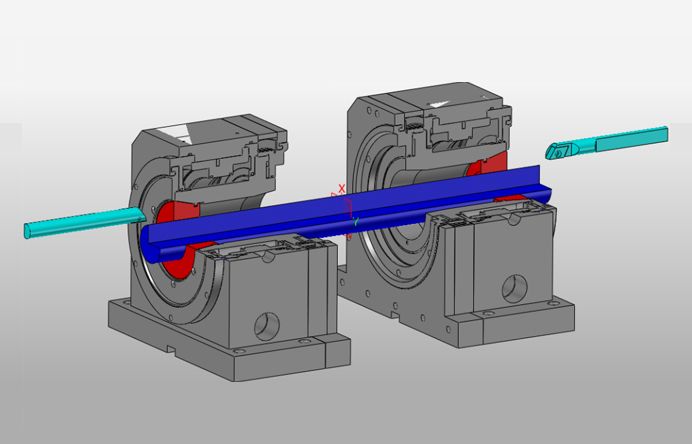

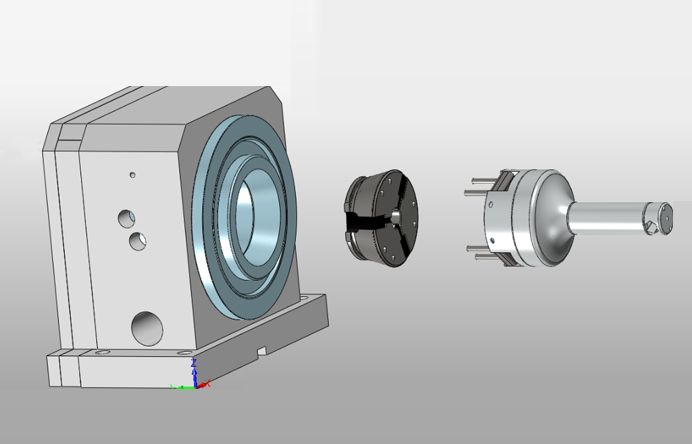

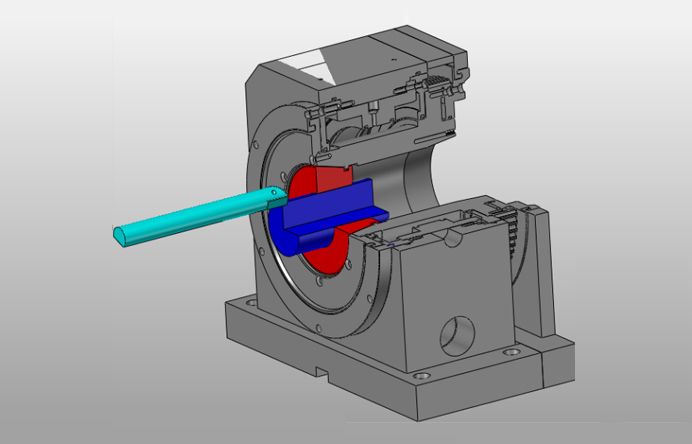

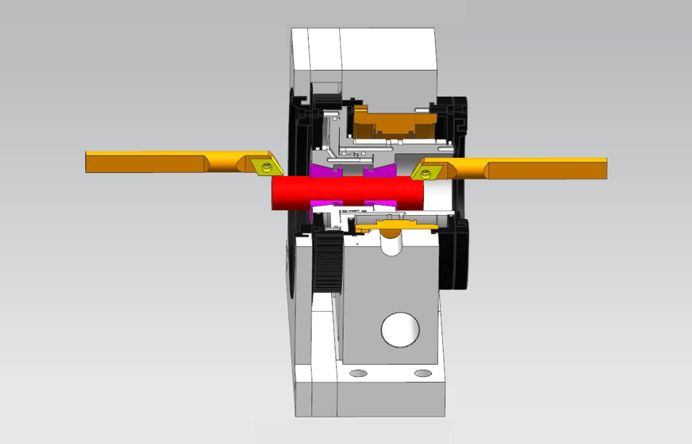

Bi-directional spindle clamp seat.Bi-directional spindle clamp seat

Product characteristics:

Product application: two-end special turning machine, spindle, shaft and sleeve processing. It is widely used in automobile, electromechanical and other manufacturing industries involving shaft applications.

Product range

Product video

Application industry

| Product Involvement in Industry | Applicable Processing Products | Product type for general use | Product Involvement in Industry | Applicable Processing Products | Product type for general use |

| automobile | Piston pins for gasoline and diesel engines | JHP-32, JHP-72, JHP-95/120 | Electric machinery | Motor shaft for starter | JHP-32, JHP-72 |

| Shock absorber connecting rod, shock absorber cylinder | JHP-32, JHP-72 | Motor Shaft Housing | JHP-72, JHP-120, JHP-160 and above | ||

| Automotive rear axle | JHP-160, JHP-180, JHP-220 | Motor Profile End Cap | JHP-72, JHP-120, JHP-160 and above | ||

| New Energy Automotive Motor Shaft | JHP-72, JHP-42/52 | Fan shaft core | JHP-32, JHP-72 | ||

| Automotive torsion bar | JHP-32, JHP-72 | Fan Motor Rotor, Stator | JHP-72, JHP-120, JHP-160 and above | ||

| Telescopic rod for back box | JHP-32 | Gearbox, Gearbox Shaft | JHP-32, JHP-72 | ||

| Steering column | JHP-32, JHP-72 | Gear shaft | JHP-32, JHP-72 | ||

| Automotive Shafts, Pipes, Sleeves, Motor Stator Rotor Parts | Whole range of products | Water pump shaft | JHP-32, JHP-72 | ||

| Electric bike, motorcycle, bicycle | Motorcycle shock absorber | JHP-72, JHP-120 | Precision Sensing Equipment | Printer shaft, copier shaft | JAN Series, JHP-20/25, JHP-32 |

| Bike pedal shaft | JHP-32, JHP-72 | Shaft and Tube Fittings for Precision Optical Medical Equipment | JAN Series, JHP-20/25, JHP-32 | ||

| Flower drum for electric bicycle | JHP-72 | Elevator. | Elevator drum | JHP-32, JHP-72, JHP-120 | |

| Rear axle of box electric vehicle | JHP-120, JHP-160, JHP-180 | Elevator drive shaft, pipe fittings | JHP-32, JHP-72, JHP-120 | ||

| Pipe fittings such as electric vehicle and bicycle handle | JHP-32, JHP-72 | Sports equipment | Treadmill drums (drums, shafts) | JHP-32, JHP-72, JHP-120 | |

| Mechanical Heavy Industry | Electro-spindle axis | Whole range of products | Other | Laser cutting and welding | Whole range of products |

| Track centre axis | Whole range of products | Logistics delivery drum | Whole range of products | ||

| Various mechanical bushings, connecting rods, cylinders | Whole range of products | Hardware Fittings, Shunt Common Rail, Pipe and Shaft Fittings | Whole range of products | ||

| Bearing holder | Whole range of products | Optical Instrument Sleeve, Logistics Conveyor Drum | Whole range of products | ||

| Track drive wheel | JHP-160, JHP-220, JHP-260 | Fishing gear, kitchen utensils, medical devices | Whole range of products |

Use legend

Basic Principles for Selecting Main Shaft

| Main Shaft Model | JH/AP-32 series | JH/AP-72 series | JHP-95 series | JHP-120 series | JHP-160 series | |

| Recommended clamping range mm | ∮5-∮32 | ∮20-∮72 | ∮30-∮95 | ∮35-∮120 | ∮100-∮160 | |

| Clamping length of workpiece | Single clip | ≤75mm | ≤90mm | ≤110mm | ≤110mm | ≤110mm |

| Double cartridge clamp | 75mm-400mm | 90mm-400mm | 110mm-450mm | 110mm-450mm | 110mm-450mm | |

| Dual spindle | >400mm | >400mm | >450mm | >480mm | >520mm | |

| Maximum rpm/min | 3000 | 2000 | 1800 | 1500 | 1000 | |

| Repeated clamping accuracy mm | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.05 | |

| Material corresponding clamping mode | Steel parts: bars/pipes with wall thickness >3mm | Oil pressure | Oil pressure | Oil pressure | Oil pressure | Oil pressure |

| Steel parts: pipe with wall thickness ≤3mm | Air pressure | Air pressure | ||||

| Copper-aluminum parts | Oil pressure | Oil pressure | ||||

| Maximum service pressurekg/cm2 | Oil Pressure 20/Gas Pressure 8 | Oil Pressure 20/Gas Pressure 8 | Oil Pressure 15 | Oil Pressure 15 | Oil Pressure 15 | |

| Clamping stroke (cylinder clamping opening and tightening motion stroke) | 1.5mm | 1.5mm | 1.5mm | 1.5mm | 1.5mm | |

| Installation angle (installation angle on machine tool) | 0-90° | 0-90° | 0-90° | 0-45° | 0-45° | |

| Main Shaft Model | JHP-180 series | JHP-200 series | JHP-220 above series | JAN series | ||

| Recommended clamping range mm | ∮100-∮180 | ∮100-∮200 | ∮100-∮220 above | ∮5-∮35 | ||

| Clamping length of workpiece | Single clip | ≤120mm | ≤120mm | ≤120mm | Double diaphragm 210mm-450mm | |

| Double cartridge clamp | 110mm-450mm | 120mm-450mm | 120mm-450mm | |||

| Dual spindle | >550mm | >550mm | >550mm | |||

| Maximum rpm/min | 800 | 700 | 600 | 1500-3000 | ||

| Repeated clamping accuracy mm | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.01 | ||

| Material corresponding clamping mode | Steel parts: bars/pipes with wall thickness >3mm | Oil pressure | Oil pressure | Oil pressure | Air pressure | |

| Steel parts: pipe with wall thickness ≤3mm | Air pressure | |||||

| Copper-aluminum parts | Air pressure | |||||

| Maximum service pressure kg/cm2 | Oil pressure15 | Oil pressure15 | Oil pressure15 | 8 | ||

| Clamping stroke (cylinder clamping opening and tightening motion stroke) | 1.5mm | 1.5mm | 1.5mm | 0.2mm--0.6mm | ||

| Installation angle (installation angle on machine tool) | 0-45° | 0-45° | 0-45° | 0-90° | ||

| Remarks | Select the spindle type: 1. First, the diameter and length of the product to be processed should be considered, and the spindle type suitable for clamping through holes should be selected. 2. Depending on the product roundness requirement, the concentricity of processing positions at both ends, and the requirement of clamping position and processing position, select the spindle that can meet the requirement. 3. When the diameter is smaller, select the spindle with high speed. If the customer needs more rotational speed of the spindle than listed in the table above, then select the bearing according to the actual situation. 4. The workpiece being processed is of softer material and more easily deformed (thin-walled pipe, copper and aluminium parts), the air press spindle must be selected. 5. Customer-specified cylinder clamping stroke can not exceed 2mm. Only the main shaft above JHP-120 can increase the clamping stroke at present. Specifically, the detailed analysis needs scheme. 6. To see if there is any axial positioning requirement for the workpiece, choose push-ahead type, add axial positioning plate or double-piston main shaft. 7. See the length of workpiece: shorter workpiece needs single-cylinder clamping, and shorter workpiece can be clamped by double-cylinder clamping. Due to the limitation of the width of the spindle, do you want to make the indented cutter penetrate the through-hole of the spindle and let it work? Does the long workpiece have single spindle and extension sleeve? Whether two sets of spindles are used for extra-long workpieces. 8. The overall selection of spindles needs to consider the compatibility of various diameters and length specifications of end-user products to select product options. 9. Evaluate process requirements and tool holder configuration, and self-simulate tool feed interference according to spindle size and installation angle. | |||||